BlizzCon & League Of Legends

Brent Armstrong Of Alpine Rigging Comments On The Benefits Of Overload Prevention On Two Top Video Gaming Conventions

Video gaming is serious business. The BlizzCon convention held in Anaheim in November and the "League of Legends Season 3 World Championship" held in Los Angeles last October are testament to that. Not only did both events attract sold out crowds, BlizzCon featured award-winning rockers Blink-182 and "League of Legends" was the most watched eSports event in history with a top prize of $1 million.

But video gaming is serious business in another aspect as well. The shows continue to get bigger and more elaborate and with that come heavier, more complex rigs. "You’re taking on a huge responsibility when you agree to hang tons of equipment like this above people," says load monitoring proponent Brent Armstrong, whose company Alpine Rigging and Structural Design handled rigging on both the BlizzCon and "League of Legends" events. "I am for anything that can increase the safety factor of a show and load monitoring certainly does that."

Brent has been hanging shows since early in the 2000s and uses industry-best practices to ensure a safe and secure show. He always incorporates Eilon Engineering’s Ron StageMaster load monitoring in the rig set up as an extra layer of safety.

BlizzCon

The BlizzCon convention, a hybrid event by Blizzard Entertainment that is half trade show and half entertainment, was held at the Anaheim Convention Center to promote their Warcraft, StarCraft and Diablo games. It was a huge 500+ chain hoist gig and Brent used 40 load cells, including 8 wireless Ron StageMaster (RSM) load cells, to monitor the rig and any unexpected shifts in weight from setup to tear down.

"The RSM was the first piece of gear I bought when I opened Alpine Rigging in 2009," states Brent, who used eight of Alpine’s own wireless RSM systems on the event and sub-rented the other load cells. "The reason I use them is for safety but also peace of mind. It provides a level of comfort for everyone involved, the rigger, the production company, the venue, the artist. It reduces exposure and minimizes liability and riggers love to see them on a show. It gives us feedback to let us know if we are accurate or not – it lets us verify the numbers and is a real teaching tool as well."

Ron StageMaster

Besides monitoring the weight of a rig, Ron StageMaster load cells can be used to check the tension in guy wires, monitor loads in human flying systems or measure the weight of set pieces. A transmission distance of up to 1 km and optional 10,000-hour battery life with no sleep mode provides an extra measure of safety and the system works even when other wireless systems are in use.

"Wireless is one of the great advantages of the system," Brent says. "I’ve tried other systems and the RSM has titanic advantages over them. Instead of using an hour to get it up and running, I can literally have the system installed in 60 seconds. It’s so simple."

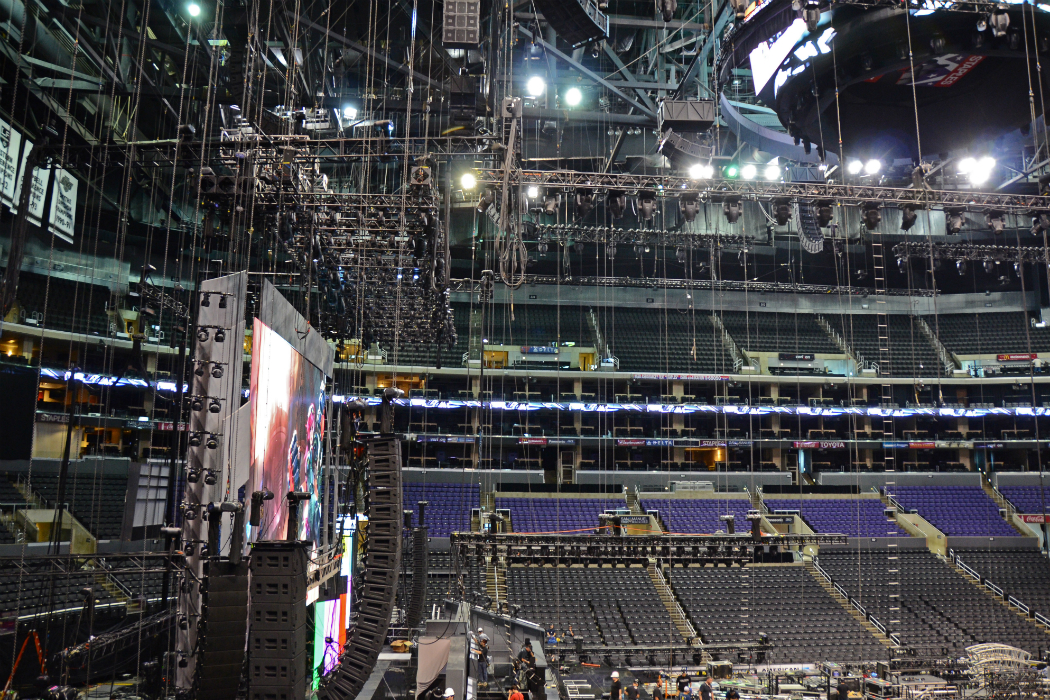

League of Legends

A month prior to BlizzCon, the "League of Legends Season 3 World Championship" took place at a sold out Staples Center in Los Angeles. A 200+ hoist, 160,000 lb gig complete with automated video wall, "League of Legends" was a large set up that mirrored the games popularity as the most played PC game in North America and Europe. With commercial breaks and even a halftime incorporated, the tournament-style event broadcast well and attracted over 32 million livestream viewers.

Here, too, Brent used 8 wireless RSM load cells with additional load cells sub-rented in. An automated video wall poses special concerns like the amount of drag placed on the system by a heavy moving object, so continuous monitoring was essential. Brent was especially concerned with the peak force drag and monitored the rig from a laptop in real time. "A lot can happen in a second with the redistribution of the weight so it’s necessary to keep an eye on the numbers." The RSM software allows for simultaneous monitoring on one screen of up to hundreds of individual hanging points, groups or the entire structure.

"I put the RSM on most of the video walls I hang, even on the smallest gigs," Brent says. "What makes an object heavy or critical is driven as much by the structure it is being supported from as the overall mass of the object. The RSM adds value and safety to every situation I use them on regardless of the overall scope or size of the project."

A case for load cells

Load cells are often looked on as the ‘cherry on top’ for gigs but they ought to be the meat and potatoes, says Brent, who feels strongly that load cells ought to have a bigger role in entertainment rigging. "My personal belief is that there is not enough quantification of what we hang. Use of the RSM load cells makes all of my data science, not guess work. The care and standard delivered on gigs varies greatly. Some have thought of every detail but others are much more slack. It can still be the Wild West out there and is largely unregulated. We need industry requirements for the use of load cells. They are a step towards elite professionalism and should have a role in every project."

Brent has seen his business quadruple in just the last year, a testament to a healthier industry but also to the growing acceptance of load monitoring. "It’s not about the profit margin. I still use load monitoring when it is not billable," he concludes. "It’s not a marketing point but a piece of a comprehensive system that makes things safer and gives everybody involved peace of mind."

For more information please contact your local Eilon representative or Noga Eilon-Bahar at:

E-mail: neb@eilon-engineering.com

Mobile: + 972-528-901851

Office: +972-4-8577720

Web: www.eilon-engineering.com

.png) Barcelona Jan 30-Feb 2

Barcelona Jan 30-Feb 2